we service in

Valve Repair and Service for Tyre Industries

Looking for unparalleled valve and Rotary Joint repairs? At Inspen, we cater to various brands like Rockey, Sinclair Collins, Sasco, Valas, Vita, Dembla, and Deublin. Mastering 3-Way, 4-Way, Flow Control, Pressure Regulating, Check Valves, we ensure quality by testing at rated pressure. All services carry a six-month warranty. Our edge? In-house manufacturing using a state-of-the-art CNC machine shop, crafting precise custom parts. Count on our commitment to excellence – top-notch repairs and high-quality replacements. Trust Inspen for reliability, technical prowess, stringent quality control, and customer satisfaction. For valve repairs or custom parts, choose us for unmatched service and dependability. Click for more!

BEFORE

AFTER

Pressure Regulating Valve for Agricultural Pesticide Sprayers

Inspen offers unparalleled valve and Rotary Joint repairs for various brands, including Rockey, Sinclair Collins, Sasco, Valas, Vita, Dembla, and Deublin. Specializing in 3-Way, 4-Way, Flow Control, Pressure Regulating, and Check Valves, they ensure quality through pressure testing and provide a six-month warranty. With in-house manufacturing using a state-of-the-art CNC machine shop, Inspen delivers precise custom parts. Their commitment to excellence, technical prowess, and stringent quality control make them a reliable choice for valve repairs and custom parts. Choose Inspen for top-notch service, high-quality replacements, and customer satisfaction. Click for more information.

Valve Repair and Service activities to other Industries

Seeking flawless performance for critical machinery? Discover Inspen Technology! Specializing in precision valve and rotary joint repairs, we’ve been tire industry stalwarts, ensuring smooth operations for esteemed manufacturers. Now, our expertise expands beyond tires to paper, food, and chemical sectors.

Our edge? Seasoned technicians adept in diagnosing and fixing intricate valve mechanisms, offering tailored solutions meeting your industry’s unique demands. Count on us for swift turnarounds, minimal downtime, and unwavering quality standards.

Elevate your operations! Partner with us for technical finesse, reliability, and dedication. Whether in tires or diverse industries, let’s optimize your machinery’s performance together. Curious for more? Click below to uncover our specialized services for the tire industry.

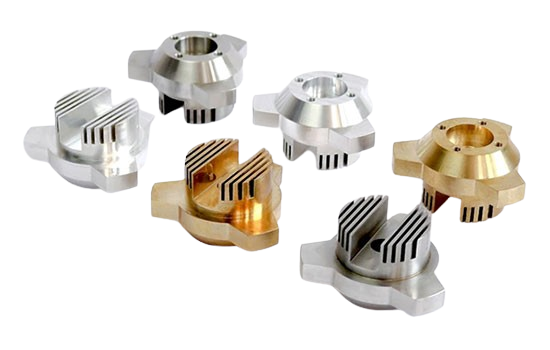

Double Hi-Flow Control Valves

Repair :

Air to Open and Air to Close type valves

Repair and Chemical Industry

Revolutionize Your Agricultural Spraying: Discover the Power of Our Precision Pressure Regulating Valve!

Looking to optimize pesticide application while preserving the environment? Our valve, ranging from 50 psi to 500 psi, is the game-changer you need. Crafted from robust stainless steel, it battles harsh conditions, resists corrosion, and stands strong against pesticide chemicals.

What’s unique? It’s the meticulous selection of internal parts, ensuring seamless operation even in chemical onslaughts. Plus, it’s user-friendly! With easy maintenance and locally available spare parts, farmers gain control, minimize downtimes, and boost productivity.

Empowering farming communities is our mission. Join us in revolutionizing agricultural efficiency and sustainability. Click to read more!

Spur Gears in Mechanical Applications

Manufacturing of Spur Gears

A spur gear is a cylindrical toothed gear with teeth that are parallel to the shaft and is used to transfer mechanical motion and control speed, power, and torque between shafts. They are the most popular types of cylindrical gears and have a simple design of straight parallel teeth positioned equally around the circumference of the cylinder barrel. There are several different designs of spur gears that change according to the shape and thickness of the gear hub, which changes without changing the face of the gear.

The performance of a spur gear is determined by its design, construction, and materials. An essential part of developing a spur gear is how they are fabricated, which includes the use of high quality materials and exacting and precise dimensional compliance that is necessary to determine a spur gear’s function.

Although there is a wide range of spur gears from very small ones to ones that operate conveying systems and motors, there are factors that are common to all spur gears, which are:

For All Your Complicated Needs

Manufacturing for Medical Industry

Like all products designed for highly critical and hazardous services, Inspen Valves’ entire range adheres to strict international standards used by industries worldwide, including ISO, API, NACE, ASME, ASTM, MSS–SP, BS EN, PED, ATEX, EEMUA, and others. Our Engineering team consistently monitors updates to these standards, integrating any relevant changes that may impact the design, regulations, and/or performance of our products.

Utilising state-of-the-art technology and tools such as Solid Works®, AutoCAD®, Inventor®, PDM®, and Finite Elements® by Ansys® system programs, our designs are crafted to ensure the proper and effective long-term performance of our products in use. From conception to calculation to detailed drawings for manufacturing – covering the entire CAD to CAM process – Inspen Valves stands as an undisputed leader in developing new products. These products are tailored to meet the dynamic needs of industries in constant motion, facing an ever-changing demand for more critical solutions as service conditions become progressively challenging, especially in handling greater depths with extremely corrosive media and products