Welcome To Inspen Tech

India's Most Trusted

Aerospace Component Manufacturer

We at Inspen Technology specialize in delivering high-quality aerospace components and aerospace parts designed to meet the rigorous demands of the aviation and aerospace industries.

With state-of-the-art facilities and unmatched expertise, we are a leading name in aerospace parts manufacturing and trusted by aerospace engine manufacturers worldwide.

Expertise in Aerospace and Aircraft Components

At Inspen Technology, we pride ourselves on being at the forefront of producing precision-engineered aerospace and aircraft components. Our unwavering commitment to precision and innovation has established us as industry leaders in the production of critical engine parts components, precision gears, gear trains, planetary gearheads, BLDC motors, essential connectors and machining of exotic high-strength aerospace materials.

Manufacturing Used for Aerospace and Aircraft Components

Our manufacturing process for aerospace and aircraft components integrates cutting-edge technologies to deliver superior results. We excel in deep-drawn aerospace component production, ensuring precise specifications, robust materials, and tight tolerances to meet diverse requirements.

Deep-Drawn Aerospace Component Highlights:

- Specifications: Customizable to meet exact needs.

- Materials: A broad selection of high-performance aerospace materials.

- Tolerances: Stringent tolerances for critical applications.

Premium Materials for Aerospace Component Manufacturing

To ensure peak performance and reliability, we use a diverse range of aerospace-grade materials, including:

- Chromium Nickel

- Aluminum Alloys

- Chromium Alloys

- Nickel Alloys

- Stainless Steel

These materials provide exceptional strength, corrosion resistance, and durability, making them ideal for critical applications in aerospace equipment.

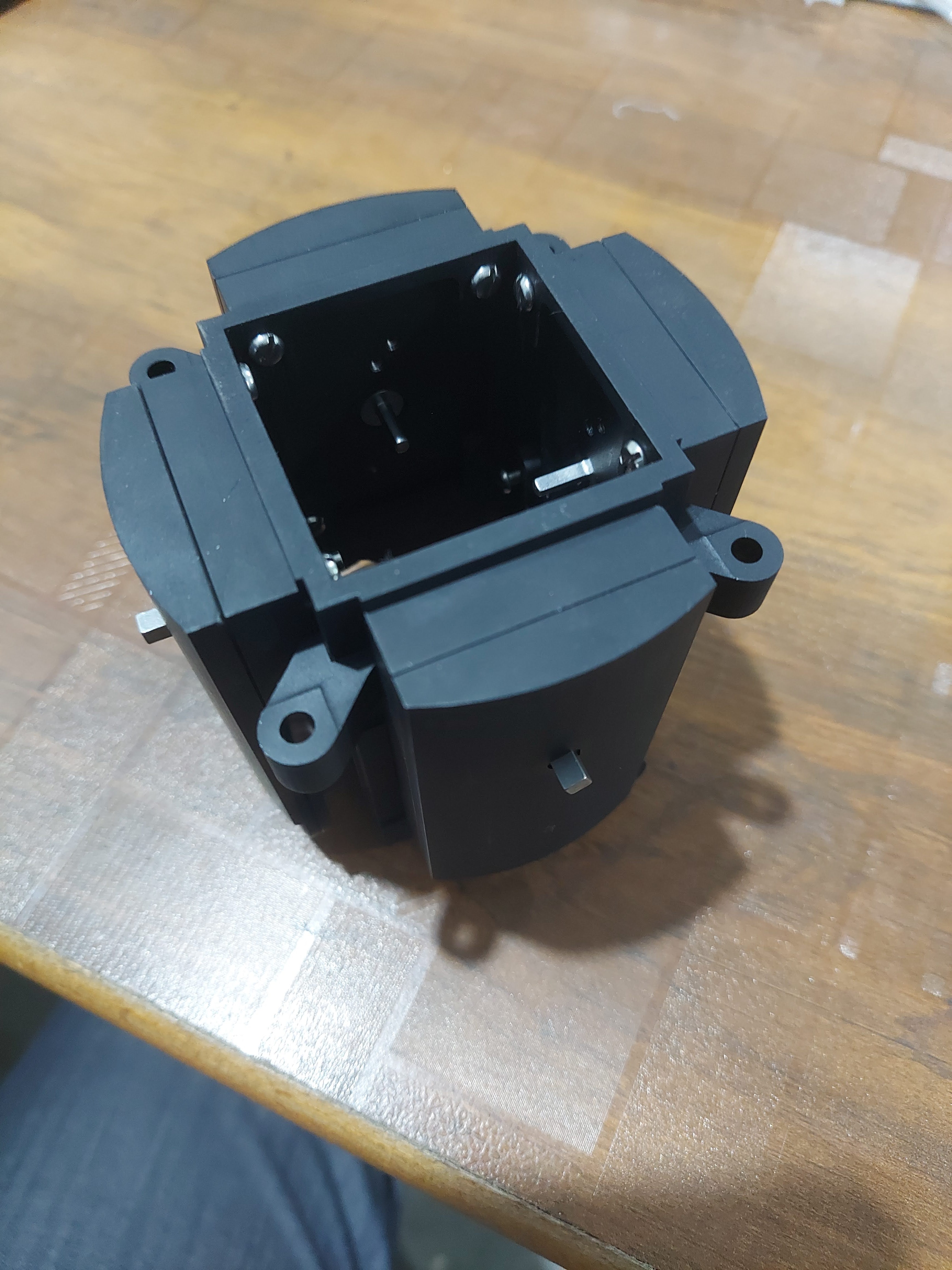

Precision Gears, Gear Trains, and Planetary Gearheads

Our capabilities extend to the intricate realm of precision gears and gear trains, including the engineering and production of planetary gearheads. Through meticulous design and state-of-the-art manufacturing techniques, we deliver gears that offer unparalleled precision, efficiency, and reliability. Our gear systems are engineered to optimize performance and withstand rigorous operational demands across various industries.

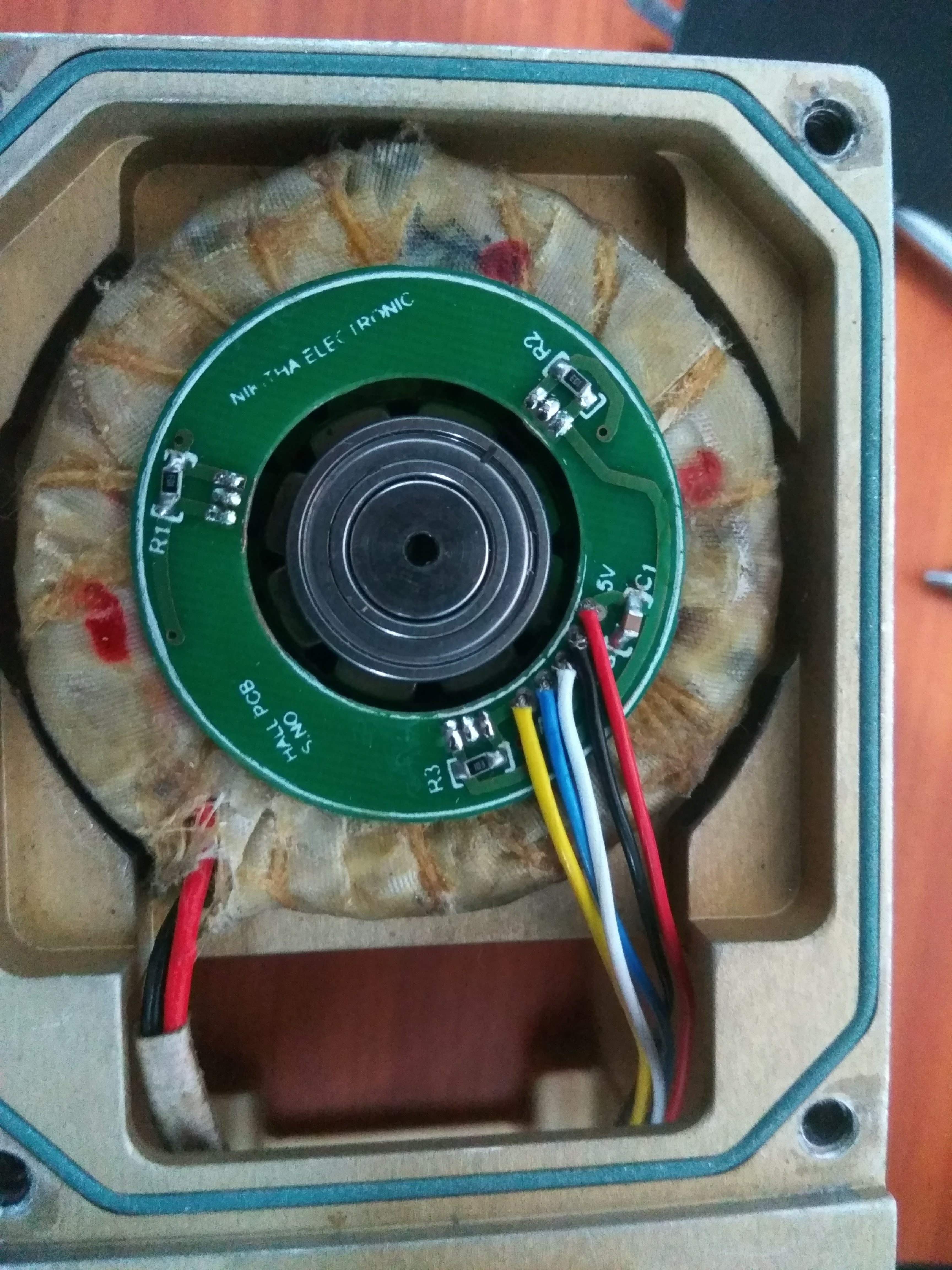

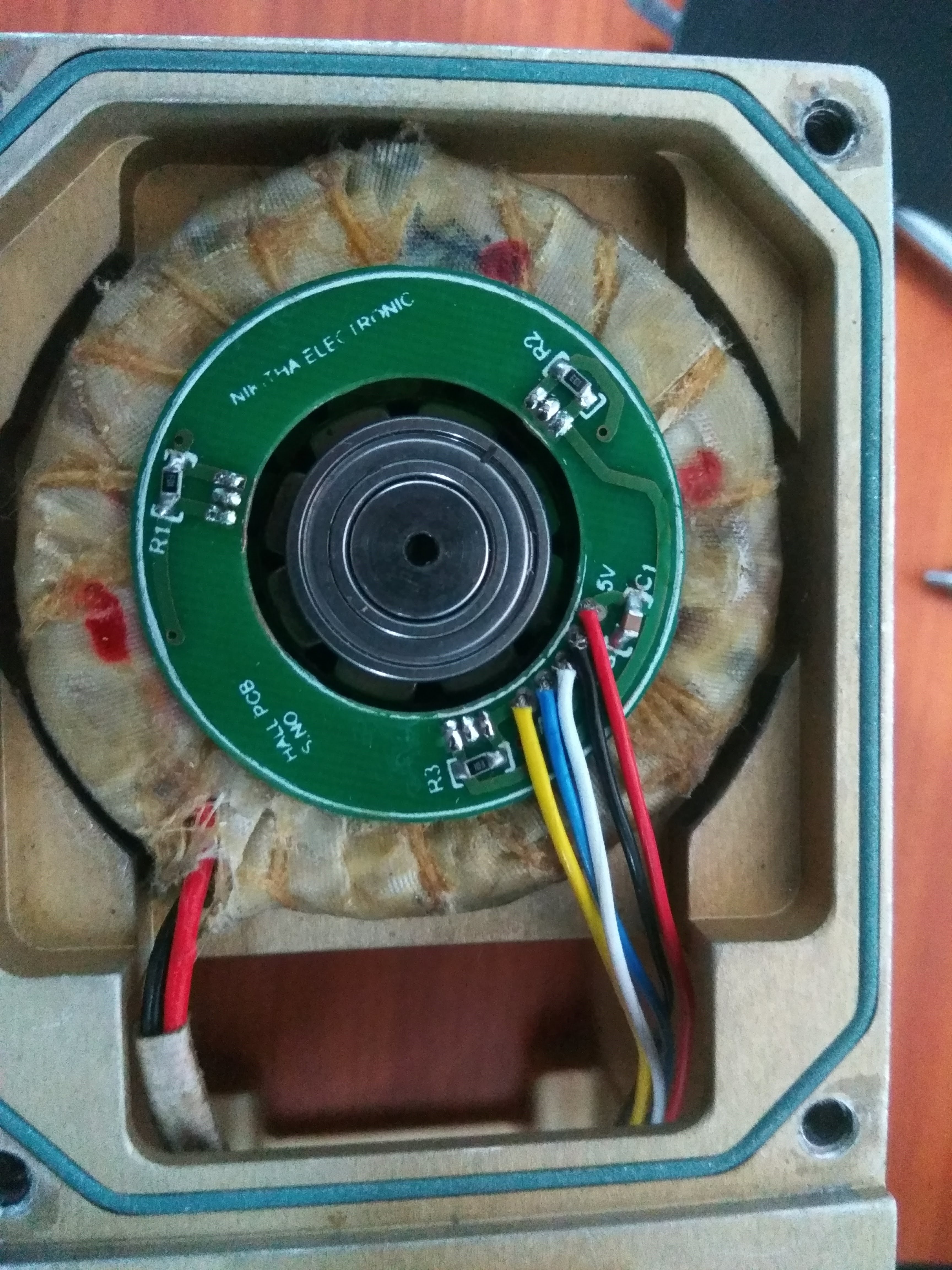

Manufacture of BLDC Motors

We excel in the production of Brushless Direct Current (BLDC) motors renowned for their efficiency, power, and reliability. Our BLDC motors are crafted with precision, incorporating advanced technologies and innovative design elements to deliver high torque and exceptional performance. These motors find applications in diverse sectors, including aerospace, automotive, robotics, and industrial automation.

Aerospace Equipment Application Areas

Our products are trusted in various aerospace equipment application areas, including:

- HV Relays

- Connectors

- Cabin Light Sensors

- Electromechanical Relays

- Engine Parts

Each component is meticulously crafted to meet the specific requirements of these applications, ensuring safety and efficiency in every operation.

Expertise in Machining Exotic High-Strength Aerospace Materials

At Inspen Technology, we possess specialized expertise in machining exotic high-strength aerospace materials. Our state-of-the-art facilities and skilled workforce enable us to handle the most challenging materials with precision and finesse. Whether it’s titanium alloys, composites, or other high-strength materials, our machining capabilities ensure the creation of components that meet the stringent requirements of aerospace applications.

Machining Exotic High-Strength Aerospace Materials at Inspentech

In the competitive aerospace industry, the demand for high-strength materials that can withstand extreme conditions is ever-growing. At Inspentech, we specialize in machining exotic high-strength aerospace materials, ensuring precision, quality, and reliability for our clients.

Understanding Exotic High-Strength Materials

Exotic high-strength aerospace materials include titanium alloys, superalloys, and advanced composites that offer superior performance in terms of weight, strength, and resistance to heat and corrosion. These materials are crucial for components in aircraft, spacecraft, and defense applications, where safety and performance are paramount.

Our Machining Expertise

At Inspentech, our team is equipped with advanced machining technologies and a deep understanding of the unique properties of these exotic materials. We utilize state-of-the-art CNC machining techniques, ensuring that each component is manufactured to exact specifications. Our experienced engineers work closely with clients to optimize designs, enhancing both performance and manufacturability.

Commitment to Quality

Quality assurance is at the heart of our operations. Inspentech follows stringent quality control protocols to ensure that every part meets the high standards required in the aerospace sector. We conduct thorough inspections and tests throughout the machining process, providing clients with the confidence that their components will perform flawlessly in the field.

Innovation and Custom Solutions

Understanding that every project is unique, we pride ourselves on our ability to offer customized solutions. Whether you need precision machining of complex geometries or specialized surface treatments, Inspentech is dedicated to meeting your specific requirements. Our innovative approach allows us to tackle the challenges posed by exotic materials, ensuring optimal outcomes for every project.

Why Choose Inspentech For Aerospace Components?

1. Expertise in Exotic Materials:** Our in-depth knowledge of high-strength aerospace materials sets us apart.

2. Advanced Technology: We leverage cutting-edge machinery to achieve superior precision and efficiency.

3. Tailored Solutions: Our commitment to customizing services ensures that we meet your exact needs.

4. Uncompromising Quality:** With rigorous quality checks, we deliver components you can trust.

Inspen Technology stands as a beacon of precision engineering and innovation in the manufacturing landscape. Our commitment to excellence, advanced technology, and skilled craftsmanship enables us to deliver superior solutions in critical component manufacturing, precision gears, gear trains, planetary gearheads, BLDC motors, and machining of exotic aerospace materials. Partner with us to experience unparalleled quality and reliability in engineering solutions that drive industries forward.

Join hands with an industry leader to achieve unmatched quality and performance.

Reach out for more details. Empower your aerospace innovations with our expertise!

Frequently Asked Questions

1. What is Aerospace Component Manufacturing?

Aerospace component manufacturing involves the design, engineering, and production of high-precision parts used in aircraft and aerospace systems. These components range from engine parts and structural elements to specialized systems like relays and sensors.

2. Who are the OEM Aerospace Manufacturers?

Original Equipment Manufacturers (OEMs) in aerospace are companies that design, produce, and assemble aircraft or their major systems. Inspen Technology, as a leading manufacturer in India, partners with these OEMs by supplying precision components that meet global standards.

3. What is Aerospace OEM?

An Aerospace OEM refers to a company that designs and manufactures complete aircraft, engines, or critical systems used in aviation. OEMs are responsible for the development and assembly of these large-scale systems, which are then integrated with high-precision components

4. Which Are the Best Aircraft Parts Manufacturing Companies in Bangalore?

Bangalore, known as the aerospace hub of India, is home to several leading aerospace parts manufacturers. Among them, Inspen Technology stands out.

5. What Materials Are Commonly Used in Aerospace Component Manufacturing?

Aerospace components are typically made from high-performance materials to ensure strength, durability, and resistance to extreme conditions. The most commonly used materials include: Aluminum Alloys, Titanium Alloys, Stainless Steel, Nickel Alloys

What Makes Inspen Technology a Leading Aerospace Component Manufacturer?

Inspen Technology combines state-of-the-art manufacturing, precision engineering, and a commitment to global standards. Its advanced materials, tailored solutions, and adherence to quality certifications ensure reliability. Partnering with top aerospace OEMs solidifies its position as a trusted name in the industry.